Designing for Depth: Engineering Tall Aquariums

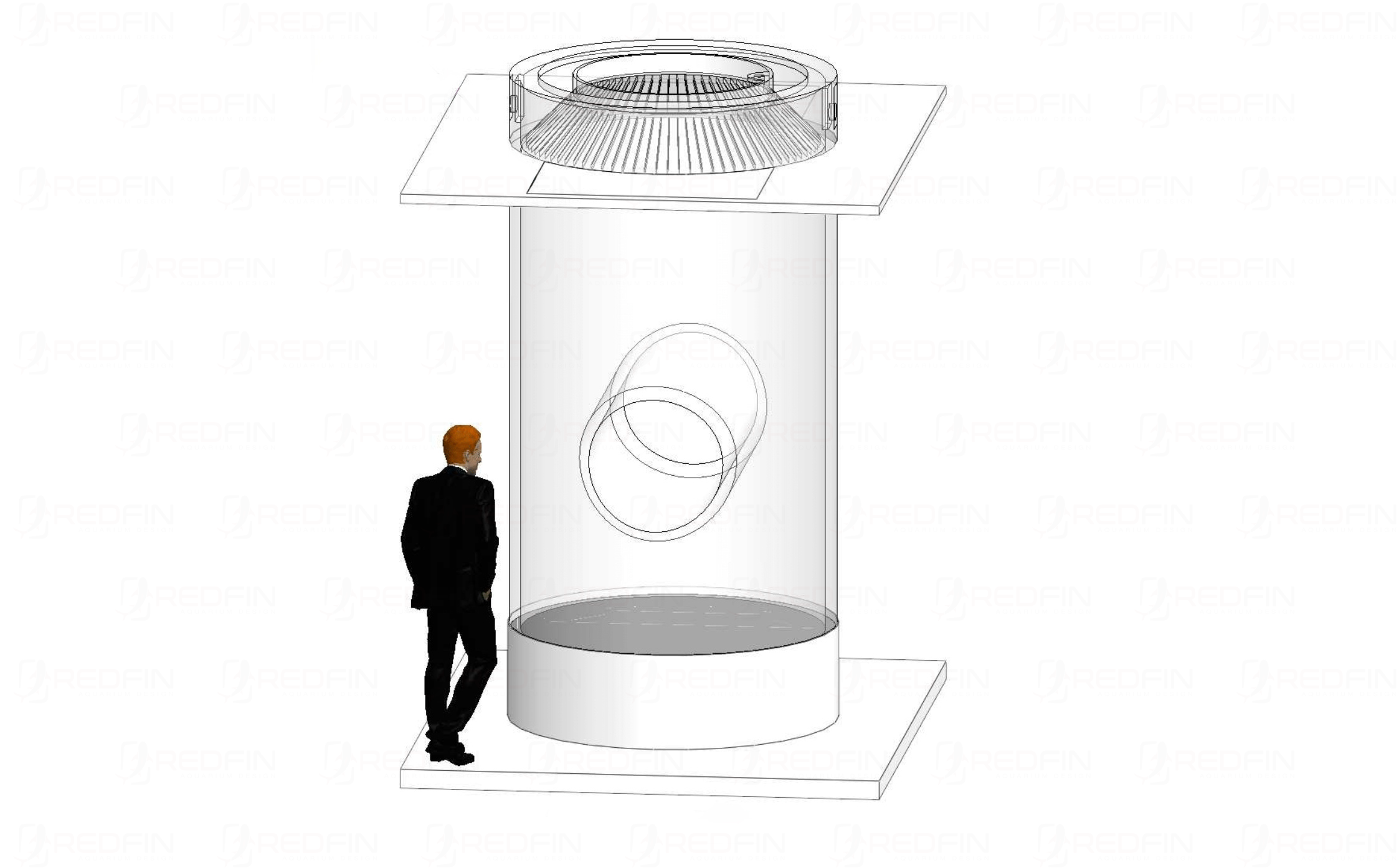

Aquarium design has evolved far beyond simple glass boxes. Today, one of the most visually striking trends in public and private installations is the tall or vertical aquarium, a bold architectural feature that commands attention and creates a unique underwater experience. However, creating a tall aquarium requires more than visual ambition; it demands advanced structural engineering, precise life support calibration, and expert integration with its surrounding architecture.

In this blog, we explore what it takes to design, engineer, and operate tall aquariums, showcasing the expertise and innovation required for these complex builds.

The Allure of Vertical Aquariums

Tall aquariums, often cylindrical or columnar in shape, offer a dramatic visual experience by emphasizing vertical movement and scale. These designs are frequently used in hotel atriums, commercial lobbies, shopping malls, and luxury residences. When done right, they become iconic centerpieces, drawing visitors into a tranquil world of aquatic life.

But behind that seamless beauty is a rigorous process involving advanced materials, pressure calculations, and life support system engineering.

Structural Considerations: Pressure, Weight, and Material Selection

One of the biggest challenges in tall aquarium design is managing water pressure. Water exerts pressure of roughly 0.1 bar per meter of depth. That means a 10-meter-tall tank exerts approximately 1 bar of pressure at its base, equivalent to atmospheric pressure. As a result, materials and joints must be engineered to withstand constant, high-intensity forces.

Key Design Factors:

Material Thickness and Type: Acrylic is preferred over glass for its strength, flexibility, and optical clarity at scale. The taller the aquarium, the thicker the acrylic must be.

Joint Engineering: Tall tanks often require seamless bonding or lamination of acrylic panels, using high-grade adhesives with minimal optical distortion.

Base Support: The structure must support not just the tank but the immense weight of water (1,000 kg per cubic meter). Engineering calculations must account for dead loads and live loads, especially in earthquake-prone zones.

Acrylic vs. Glass: Why Acrylic Wins for Height

For tanks over 2 meters in height, acrylic becomes the material of choice. Unlike glass, acrylic can be heat-formed into curved shapes, offers better impact resistance, and is significantly lighter, making it easier to transport and install. More importantly, acrylic maintains clarity even in thick panels, whereas glass often becomes visibly greenish at greater thicknesses due to iron content.

Engineering the Life Support System (LSS)

Tall aquariums pose unique challenges in water circulation, oxygenation, and temperature regulation. Uneven flow patterns can lead to stagnant zones or thermal layering, where water at the top is warmer than at the bottom, detrimental to livestock health.

LSS Features for Tall Tanks:

Vertical Water Circulation Systems: Strategically placed jets or upward flow pumps ensure even water distribution.

Oxygenation Systems: Diffusers and protein skimmers are calibrated based on depth, as oxygen levels vary at different heights.

Redundant Filtration: High-performance mechanical and biological filters are essential to maintain water quality in large volumes.

In most cases, a dedicated equipment room houses pumps, UV sterilizers, chillers, and filtration media to support 24/7 operation.

Livestock Considerations: What Species Work Best?

Not all aquatic species thrive in tall environments. Fish that naturally swim in vertical patterns or occupy the mid-water column are ideal for deep tanks. Examples include:

Anthias and Chromis (for saltwater)

Silver Dollars and Angelfish (for freshwater)

Jellyfish (when using a kreisel or laminar flow design)

Additionally, care must be taken to design accessible feeding and cleaning systems, such as automated feeders or diver access protocols, especially in tanks taller than 5 meters.

Access, Maintenance, and Safety

Cleaning a tall aquarium isn’t as simple as wiping down the glass. These tanks often require:

Specialist Divers: RedFin deploys trained aquarists and divers for deep-tank maintenance.

Safety Harnesses & Scaffolding: For above-tank access and lighting adjustments.

ROV Systems: In some cases, small remotely operated vehicles are used for internal inspection.

A smart maintenance strategy includes redundancy in life support systems, emergency power backups, and remote water quality monitoring.

Integration with Architecture

Tall aquariums must complement and enhance the building they’re housed in. That means close collaboration with architects, structural engineers, and interior designers from the start of the project.

Key areas of coordination include:

Load-Bearing Floor Systems

Lighting Integration (natural and artificial)

HVAC Compatibility

Emergency Draining & Overflow Systems

RedFin specializes in early-stage collaboration to ensure the aquarium becomes a seamless part of the design language.

Conclusion

Designing tall aquariums goes far beyond visual impact. It’s an intricate process that combines hydrodynamics, materials science, architecture, and marine biology. RedFin’s global expertise in delivering these technically demanding projects ensures both long-term performance and stunning aesthetics, making vertical aquariums a true fusion of engineering and art.