Custom Acrylic Aquariums: Benefits, Drawbacks, and Key Considerations

Choosing the right material is one of the most important decisions when designing a custom aquarium. While glass has long been a popular option, acrylic aquariums have become the go-to choice for large-scale and uniquely shaped installations due to their strength, clarity, and design flexibility.

At RedFin, we’ve delivered world-class aquarium projects across 25+ countries, many of which rely on acrylic to bring ambitious designs to life. But while acrylic offers many advantages, it's important to weigh both its benefits and limitations before making a decision.

Why Choose Acrylic for Custom Aquariums?

Acrylic (also known as polymethyl methacrylate or PMMA) is a transparent thermoplastic used in a wide range of architectural and display applications. In aquariums, it’s favored for its lightweight strength, seamless appearance, and creative flexibility, particularly for large or curved tanks.

Benefits of Acrylic Aquariums

1. Strength and Impact Resistance

Acrylic is up to 17x stronger than glass and far less likely to shatter. This makes it safer for high-traffic public environments and ideal for tall or high-pressure installations.

Our 4-meter-tall reef aquarium for a private residence required pressure handling that acrylic could support without compromising visibility or safety.

2. Lightweight for Large Builds

Acrylic weighs around 50% less than glass, which significantly reduces the structural load on flooring and support systems. This is critical in buildings with weight restrictions or elevated platforms.

3. Design Flexibility

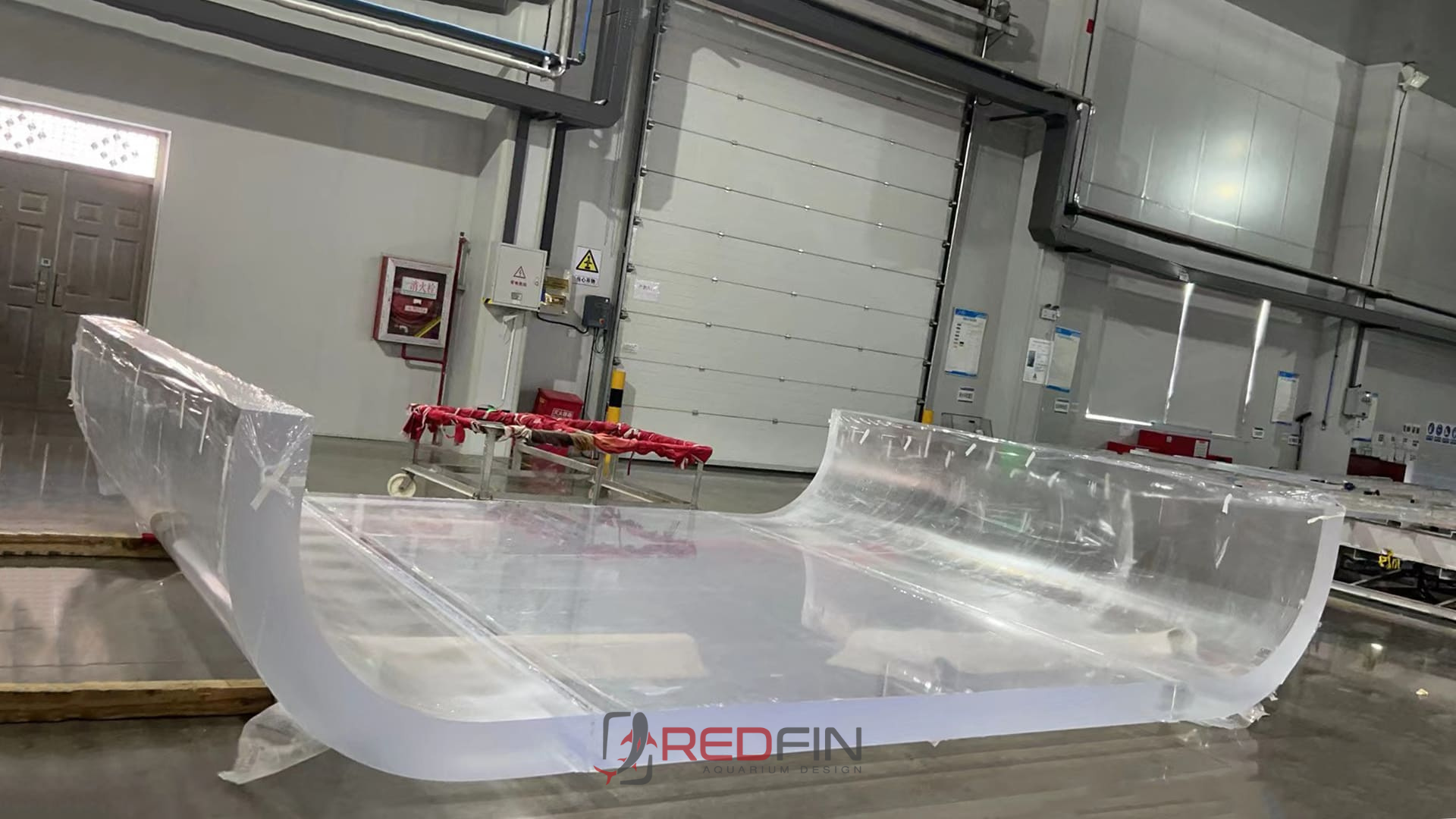

Unlike glass, acrylic can be bent, molded, or thermoformed into curved panels without losing clarity or distorting the view of what’s inside. This allows for unique shapes such as:

Cylindrical or semi-cylindrical tanks

U-shaped or tunnel-like features

Panoramic viewing windows

Infinity or rimless designs

This versatility makes acrylic a natural choice for architectural and artistic aquarium builds.

4. Optical Clarity

Acrylic offers superior clarity, particularly for thick panels. Glass over 19mm can appear green or distorted, while acrylic remains crystal clear, even at thicknesses exceeding 100mm.

This is especially important for public viewing tanks or high-end residential installations where aesthetic purity is a priority.

5. Seamless Panel Bonding

Acrylic panels can be chemically bonded to form nearly invisible seams far cleaner than silicone-sealed glass joins. This enhances both visual continuity and structural strength.

Drawbacks of Acrylic Aquariums

1. Scratch Sensitivity

Acrylic is more prone to surface scratching than glass. Even standard cleaning tools or decorations can cause marks if not handled carefully. However, unlike glass, acrylic can be polished to remove most scratches, making it easier to restore its clarity and appearance giving an acrylic tank a much longer lifetime.

2. Higher Cost

For the same size and volume, acrylic tanks are typically more expensive than glass due to the material cost and fabrication complexity. However, for large builds, the cost difference often becomes justified by the weight and strength advantages.

3. Susceptible to Chemical Damage

Acrylic can be affected by strong solvents, alcohol, or ammonia-based cleaners. It requires specialized maintenance products to avoid surface damage.

4. Expansion and Flex

Acrylic expands slightly with temperature and pressure, which means it must be engineered with tolerances in mind, particularly in large installations.

Key Considerations When Buying a Custom Acrylic Aquarium

If you’re considering an acrylic aquarium, especially a large or custom-shaped build, here are the most important factors to consider:

1. Panel Thickness

Thicker panels are needed for taller tanks to withstand pressure. Always work with an experienced fabricator who understands load-bearing calculations and industry safety margins.

For example, a 3-meter-high acrylic panel may require 80mm or more in thickness, depending on length and volume.

2. Support Structure

Despite being lightweight, acrylic still requires precise support frames to prevent bowing or stress on seams. Floors must be level, and joints must be stress-relieved to avoid cracking.

3. Manufacturer and Bonding Quality

Not all acrylic tanks are made equal. Look for:

True cell-cast acrylic (not extruded)

Seamless molecular bonding

Proven references and large-tank experience

At RedFin, we only use the highest-grade acrylic, and our fabrication partners follow strict international standards for clarity and pressure integrity.

4. Access and Transport

Large acrylic tanks are often built in sections or onsite due to their size. Consider access routes, doorways, elevators, and cranes if needed.

5. Long-Term Maintenance Plan

Factor in a cleaning and scratch management plan from day one. Use acrylic-safe cleaning tools to avoid damage. Keep clear acrylic polishing kits on hand for light abrasions, and schedule regular inspections to check clarity, joints, and structural integrity.

Where Acrylic Makes the Biggest Impact

Acrylic is particularly well suited for:

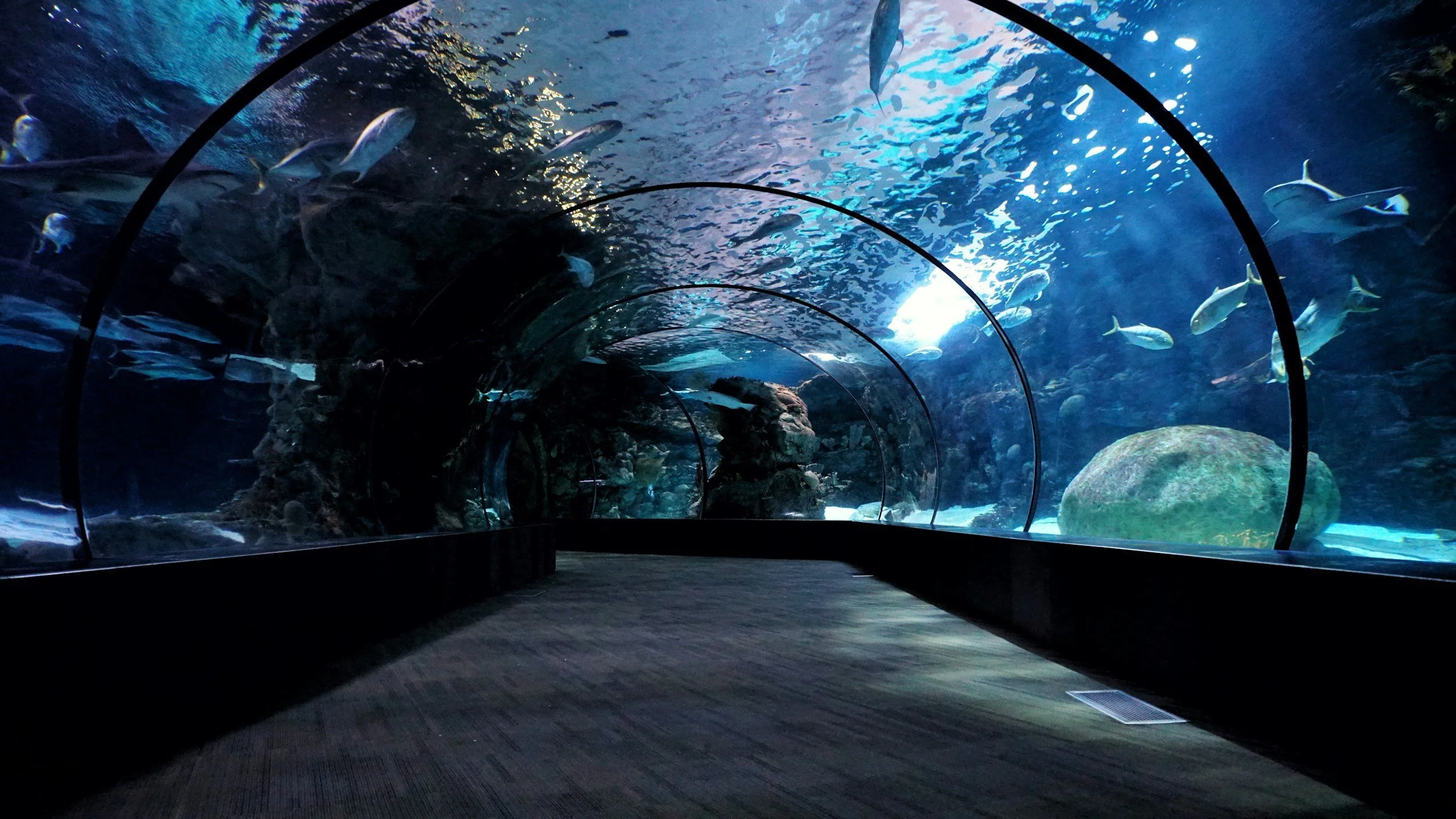

Large public aquariums

Tall or cylindrical feature tanks

Curved installations (e.g. hotel lobbies, shopping malls)

Luxury residence showpiece tanks

Underwater tunnels or windows

Acrylic is a powerful material that unlocks new possibilities in custom aquarium design. With its strength, clarity, and creative freedom, it’s the preferred choice for many of RedFin’s most ambitious installations.

However, the success of an acrylic aquarium depends on precision engineering, expert fabrication, and informed maintenance. At RedFin, we guide clients through every stage from concept and material selection to fabrication, installation, and long-term support.

If you're considering a custom acrylic aquarium, get in touch with our team to explore what’s possible and how we can help you achieve it.